Over the last eight years Forge Motorsport have grown in to one of the UK’s premier manufacturers of products and accessories for race, competition and road vehicles.

All Forge production is carried out in house and controlled by the international standard ISO 9002 for manufacture design and development. With this quality approval in place Forge continues with its commitment to bring the best products and manufacturing processes to the UK, Europe, North America and now to India.

All Forge products are guaranteed for life with the Forge “No Hassle” service promise.

Over the last two years Forge have opened a sales and distribution facility in Orlando USA and increased the production and development facilities in the UK to allow them to better serve their growing customer base. This year Forge are investing heavily in their Research and Development facility in order to embrace the very latest technology.

When you purchase from Forge Motorsport you are assured of quality products and a service to match. If you require a particular product that is not listed in this catalogue or on the web site, please call or email and we will gladly assist with any queries.

Forge Motorsport offer Front Mount Intercoolers (FMIC) which because of their location at the front of the car allow greater charge air cooling. Also available is side mount intercoolers which although located in the same position as your standard intercooler on the 1.8T engines, these are larger and again capture more air.

For the new 2.0 L FSIT engines there is one sure way to improve on the charge air cooling by using the Forge “TWINtercooler” this ground breaking innovation features a unique twin-core design which has added greater efficiency throughout the entire RPM band beyond that of a single core setup. Forge have achieved this by using the latest core technology with high flow end tank designs to achieve a huge reduction in inlet temperatures.

Forge spent many months testing various designs and the Twintercooler design emerged as the clear winner. This is a bolt-on kit that retains the use of the OEM intercooler to produce both horsepower AND torque, but more importantly, a HUGE reduction in inlet temperatures and increased flow efficiency.

A reduction in temps of up to a peak of 20 degrees Fahrenheit from 102 to 82 at 6600 RPM!

[nggallery id=10]

All VAG 2.7 Bi-Turbo engines

Porsche 911/996 turbo

Made from billet aluminium, this recirculating diverter valve dumps the charge-air back into the air intake system keeping external noise to a minimum. This increases both quicker throttle response and higher clamping load to maintain boost pressure more reliably.

Made from billet aluminium, this recirculating diverter valve dumps the charge-air back into the air intake system keeping external noise to a minimum. This increases both quicker throttle response and higher clamping load to maintain boost pressure more reliably. Unlike diaphragm diverter valves, this uses counter balanced springs and a single piston to prevent the valve from leaking air into the intake system at idle. This prevents our diverter valves suffering any of the failures associated with single piston and diaphragm type diverter valves

This valve uses a Copper and Zinc alloy piston which utilises new sealing technology along with a variable spring preload incorporating a ratchet type top adjuster that will allow for the positive and precise adjustment to match the valve to your engine. This is achieved by using a unique single, conical, progressive rate spring that can allow for the retention of boost pressure over a wide adjustment range. This unique spring design also allows for unrestricted piston travel and flow volume regardless of the amount of pre-load adjustment added to the spring. Other manufacturers valves using cylindrical springs with adjustable pre-load often experience restricted piston travel and a reduction in flow volume.

We have spent the last year co-developing a range of vehicle specific hoses with silicone manufacturer SiliconHoses.com guaranteed to rival the best offerings from any other manufacturer on the market today in terms of quality, price, and most importantly, performance.

The internal surface of the hose is completely smooth and unobstructed and the internal volume of this hose has been increased to provide the highest level of airflow at all points within the power band. We have also taken extra care to ensure consistency between each hose produced and that each hose includes all of the necessary ports and provisions required for each engine code and application as have often times been missing on hoses from other manufacturers.

Each Forge Motorsport Induction Hose is available in your choice of 3 colours to match the tastes and desired colour themes that you are looking for.

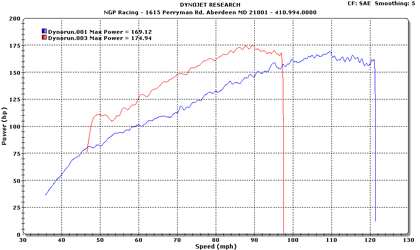

Dyno testing has been performed, by independent reviewer and Forge dealer NGP Racing on their in-house DynoJet dynamometer. Testing was performed on a 2003 Jetta 1.8T with an AWP engine code. The vehicle modifcations include Cold Air Intake, 2.5″ Turbo-Back Exhaust, Forge 004 Blow-off Valve, N75J Valve. For the benefit of those without engine software modifications testing was conducted with stock ECU software.

Dyno runs 1 and 3 compare a baseline (OEM hose) to the addition of the Forge induction hose using the stock ECU as programming.